What Does Insulated Spandrel Panel Mean?

from curtain wall movements (thermal, structural), prolonged direct exposure to water (great drain attributes lower this threat), heat/sun/UV degradation (age). Repairs (if possible) need considerable disassembly of drape wall (insulated metal spandrel panels). If remediation of internal seals is not physically feasible or otherwise economically practical, installation of exterior surface wet sealing in any way glazing and also frame joints is commonly carried out.

Repair services need outside gain access to. Light weight aluminum structures are inherently corrosion resistant in many environments if anodized and properly sealed or repainted with baked-on fluoropolymer paint. Aluminum structures undergo damage of the covering as well as corrosion of aluminum in severe (industrial, coastal) settings as well as galvanic corrosion from call with different steels.

Curtain walls and perimeter sealers need upkeep to optimize the life span of the drape wall surfaces. Perimeter sealants, effectively made as well as mounted, have a common solution life of 10 to 15 years although breaches are likely from the first day. Elimination as well as replacement of boundary sealers calls for meticulous surface prep work and also proper outlining.

Manufacturing facility used fluoropolymer thermoset coverings have excellent resistance to ecological destruction and also need just regular cleaning. Recoating with an air-dry fluoropolymer covering is feasible however needs unique surface area preparation and also is not as durable as the baked-on original covering. Plated light weight aluminum frames can not be "re-anodized" in position, but can be cleansed and safeguarded by proprietary clear coatings to enhance appearance as well as resilience.

The most effective method for sustainability of drape wall surfaces is to employ great style techniques to make certain the toughness (optimum solution life) of the installation as well as to make use of systems that have an excellent thermal break and high R-value (worths as high as R-7 are feasible with triple-glazed systems). Likewise, the usage of low-e and spectrally careful glass coverings can significantly lower energy loads as well as improve comfort near to the wall surface.

The Ultimate Guide To Insulated Spandrel Panel

Recover and also demolition specialists generally need a minimum of 1,000 sq feet or more of window/curtain wall to make material recycling affordable (smaller sized quantities are generally gotten rid of as general garbage). Recycling is much less economical if the light weight aluminum is contaminated with sealants, broken glazing, etc., as salvage firms pay significantly much less for the material.

Select a drape wall with a demonstrated track document in comparable applications as well as direct exposures. Confirming track records might require significant research study by the designer. ASTM E1825 provides guidance. Review lab examination outcomes of systems or comparable customized systems for air, water, and structural resistance, warmth transmission, condensation resistance, audio transmission, and also operability.

Drape wall layout should begin with the presumption that external glazing seals, perimeter sealer joints and drape wall surface sills will leakage. The complying with sums up advised attributes: Select frameworks with wept glazing and pocket sills sloped to the outside to accumulate water that penetrates the glazing and drain it to the outside.

Each glazing pocket should be completely isolated from surrounding glazing pockets. Offer a sill flashing with end dams as well as with an upturned back leg showed up into the glazing pocket at the base of the curtain wall to gather and drain pipes curtain wall surface sill leakage; provide jamb flashings to direct boundary leakage down to the sill blinking.

Use as lots of 1/4-inch by 2-inch ports as needed for pressure-equalized systems. Layout the drainage system to handle condensation as well as rainfall. Drape wall perimeters need to have flashings (sill, jambs and head) that are secured to the air as well as water obstacle at nearby walls. Incline head and sill flashings to the exterior to promote drain.

The Ultimate Guide To Kawneer Spandrel Panel Metal Spandrel

Curtain wall must have a primary air/water seal in between the shoulder of television at the plane of the glazing pocket and also the air barrier of the adjacent construction. Boundary sealants are beneficial as a rainscreen for restricting air and also water infiltration with the outermost aircraft of the wall surface, but need to not be depended upon as the sole air/water penetration obstacle.

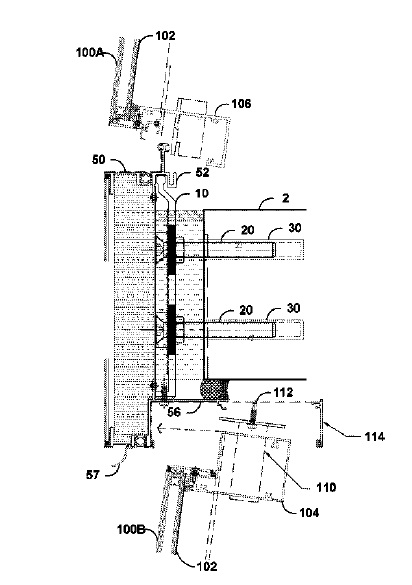

Stress Plate Glazing: In this system the glass as well as infill panels are set up from the exterior, generally versus dry gaskets. The outer layer of gaskets is set up and also the gaskets are pressed versus the glass by the torque related to fasteners safeguarding a constant pressure plate - curtain wall spandrel panel detail. Home plate is later generally covered with a snap-on mullion cover.

For enhanced performance four-sided gaskets can be made at added expense or wet sealants can be set up to supply a concealed interior toe grain or revealed indoor cap beads. Pressure plate glazing allows the most convenient method to secure an air obstacle from nearby construction right into the air barrier of curtain wall surface system.

The structure is fixed and also exterior completely dry gaskets are installed. Usually just the leading interior mullion has a removable quit. The glass unit is glided into a deep glazing pocket on one jamb far enough to permit removing the opposite jamb and is after that relapsed right into the opposite glazing pocket and afterwards went down into the sill glazing pocket.

Sometimes this approach is called "agitate" or "wiggle" glazing due to the fact that of the control required to get the glass into area. gable spandrel panel. Efficiency is somewhat decreased because dry metal to steel joints take place at the ends of the removable quit at a factor that ought to properly be air and also watertight. Wet sealant heel grains will enhance performance and also some systems consist of an additional gasket to develop an air barrier seal. 2. A nontransparent bulkhead not less than 18 inches (457 mm) greater than the top level. 3. A solitary horizontal bar of handrail strength demands not much less than 11/2 inches (38 mm) in size determined alongside the airplane of the glazing and located in between 24 inches and also 36 inches (610 and 914 mm) above the top degree.

Insulated Spandrel Panel Detail - Truths

A planter with plantings not less than 18 inches (457 mm) greater than the upper degree. R4410.2.4.3 Glazed panels situated beside, or in doors, will be of safety and security glazing, based on the following: 1. All glazed panels where a 3 inch (76 mm) diameter round has the ability to pass.

In all tenancies, any kind of glazing product beside door within 48 inches (1219 mm) of the door in the shut setting and listed below the top of the door. Exemptions: 1. Wired glass in fire doors. 2. Leaded glass of 30 square inches (194 cm2) or less. 3. Curved glass in rotating doors.

double glazing spandrel you can find out more link